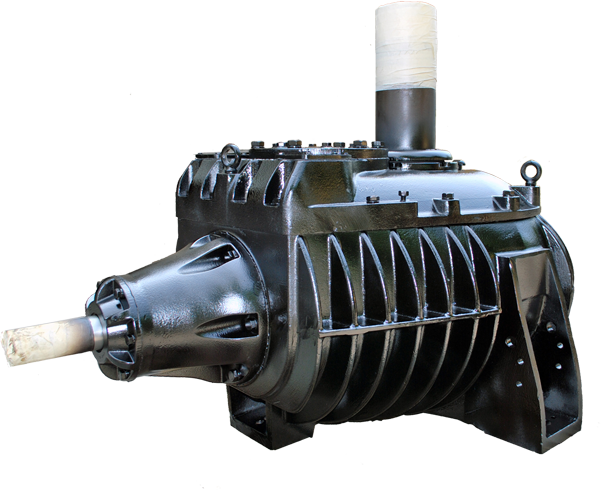

Cooling Tower Gearboxes

We know how important it is to get your cooling tower back up and running as quickly as possible!

C-B Gear & Machine has a long history of rebuilding cooling tower gearboxes. We have quick access to gears, bearings, seals, and housings for these gearboxes.

Each refurbished gearbox is guaranteed to have high quality approved parts. C-B Gear conducts a multi-level process of dismantling, cleaning, machining, and replacement of faulty parts, reconditioning and assembly. Each gear is inspected on a CNC precision gear checking machine. Cooling tower gearboxes are spin tested and contact pattern analysis is used to insure proper operation.

Common models we see are 32, 34, 36, and 38 series and all ratios.

Ask us about Marley Gearbox repair!

Procedures

- All Pictures are taken upon arrival showing any damage to housing, gears, ,shafts, bearings, caps, seals etc.

- Write-up of all issues are documented and presented to the customer notating any wear spots.

- Customer is presented with repair option and may come look at the unit to discuss any issues.

- After approval, we will thoroughly clean all components per C-B Gear & Machine procedures outlined in the report.

- Reassembly with all tolerances noted

- Spin and vibration tested

- Final Report will be provided to the customer

Replacement Gears

We offer in-house manufacturing of spiral bevel and helical gears, as well as the option to utilize customer-provided gearing for the reassembly of your gearbox. Our gears undergo a meticulous process, featuring case-carburization and grinding to AGMA 13+ standards. These gears are subjected to rigorous inspection on our dedicated in-house equipment, distinct from the grinding and milling apparatus.

Our commitment lies in delivering gears of the utmost quality for your specific application, ensuring optimal tooth contact and enabling the gearboxes to achieve peak performance.